This three-stage French fry processor produces approximately 30,000

lbs./hr. of fries. For energy efficiency, the system uses a heat recovery unit,

which passes exhaust air through an air-to-air heat exchanger to pre-heat the

dryer makeup air. Source: Aeroglide.

In a perfect world, the amount of fuel converted into energy to heat a process would be totally applied to a product, whether it’s baking bread, frying chicken or drying a cranberry slurry. Unfortunately, our world isn’t perfect, and energy losses abound in thermal processes. While conserving energy may be politically correct or “green,” most processors’ reasons for saving energy are not so altruistic. Putting more energy into the product and less into the environment cuts operating costs and directly improves the bottom line.

This gas-fired Wolverine Proctor Compak Model 2500 roaster at Warrell Corporation in Camp Hill, PA dry roasts all nuts except peanuts. A Model 2000 roaster handles peanuts exclusively.

When a processor looks for thermal equipment, product quality is the number one consideration. “I would list the [selection] criteria as final moisture control, energy savings (including reclaiming heat from the product), cost and minimum foot print,” comments Don Enstrom, senior director, manufacturing & engineering services, at Cliffstar, a private-label juice manufacturer. Controls are important to Enstrom. “Ours is a refrigerated, reduced-moisture product sold by weight. To maximize our yield of high-quality product at the lowest cost, we need equipment that can gently de-clump material, uniformly dry it to a precise setpoint and pre-cool it prior to packaging and refrigeration.”

When it comes to choosing ovens, “Our highest priority for selection will be the equipment’s ability to produce high-quality, consistent product,” says Scott Young, manufacturing engineering manager at Wegmans Food Markets. “Given this priority, close consideration will be given to the type of automation and controls that are included to achieve the level of quality and consistency.”

Tight control is a must in the snack food industry, which, according to Don Giles, direct sales, processing systems, Heat and Control, means tenths of a percent in moisture content levels. With potato chips, for example, target moisture content might be 1.5%. But if the cooking process results in 2% moisture content, the product probably won’t be as shelf-stable as it should be. “Yet,” Giles says, “if the cooking process yields moisture content at 1.2%, the process is probably using too much fuel.”

Oil vapor, particulates and odors from chicken fryer exhaust emissions are incinerated by KleenHeat as it heats circulating cooking oil. Source: Heat and Control

Controls drive energy savings

Controls are more sophisticated than they were five years ago, says Bob Sunderland, director of dryer technology, Wenger Manufacturing. One reason Sunderland cites is that sensors (especially for temperature and humidity) are more robust today, and they hold up much better in industrial/drying/cooking environments. Now the instrumentation “allows us to do everything on our wish list,” he says. And processors know the value of instrumentation and controls. Sunderland says most of his clients don’t need to be sold that the extra $200-300K on instrumentation spent will yield a payback. “They know through past history that the controls will pay for themselves.”For those who may not be inclined to purchase real-time, closed-loop drying systems, Sunderland says his company provides two lower-tier control systems depending on the versatility needed. A few clients still prefer the low-cost, old-fashioned push buttons (tier 1). Some like the option of a GUI-based, automated process management system-usually with some PLC functionality-with recipe capability (tier 2). For those who need full-blown PLC-based, closed-loop controls (tier 3), they’re also available at the cost premium noted above. In the knowledge-based, tier 3 system, the dryer makes calculations within itself in the background and asks the operator’s permission to make the final decision.

Often the decision to spend extra money for an advanced controls package is made during the capital budget planning stages. According to Matt Ruth, director of the food and beverage group at Avanceon (previously Advanced Automation), those responsible for keeping project costs low often balk at an add-on cost of $100K - $200K for advanced controls because it’s simply an added expense, and there may not be a perceived, immediate benefit. However, if plant personnel are involved early in the planning process, they will often see the benefits advanced controls bring, especially in improving the process and keeping fuel costs low.

An alternative to the cost of tier 3 controls, however, may be available to processors, says Ruth. Processors who work with system integrators (SIs) may find the SI can tap into some useful data streams provided by the thermal equipment without the need for a high-end controls package and bring enough information into the overall plant systems at a much lower cost.

Besides providing knowledge on the baking or drying process, advanced controls can keep a real-time, running tab on the amount of product being made and the amount of energy being used to make it. It’s not much of a stretch to correlate product quality (say, moisture content) and cost per pound of product being made based on fuel/energy consumption. According to Doug Schieber, Carrier Vibrating sales manager, “Everybody we’re talking to is doing this. There may be some processors out there that aren’t to that point yet, but the vast majority is making the calculation.” Schieber says 99% of his clients are deeply concerned about energy usage, and they strongly consider the necessary monitoring/controls to make this calculation. In addition to energy savings, advanced controls may reduce some of the manpower needed to operate the equipment.

An add-on to controls-based equipment, thanks to the Internet, is remote troubleshooting, a time-saving function that allows suppliers to interpret why a processor’s system has gone off target and is using too much energy, says Joe Mistretta, president of FOODesign Machinery and Systems. “We are able to monitor a customer’s equipment to make sure the system is operating at its highest efficiency and, if needed, make adjustments by accessing the control system through a Web portal.”

One person who has monitoring and controls down to a science is Richard LaFond, executive vice president of BioSan Laboratories, a producer of nutritional products MegaFood Daily Foods and MegaFoods Essentials sold in the US and Europe. A 50-ft. long MCD Technologies PLC-based dryer provides the processor with the information to monitor energy consumption and product quality. “We track both gas and electrical usage around the clock and have developed a simple Excel spreadsheet that allows us to put in the energy and labor consumption and the cost of each, and match it against the kilos produced.”

By monitoring the plant’s energy use under various conditions (for example, with the processing equipment running and the heat and air conditioning not running), he is able to accurately calculate the baseline energy use for the plant and, therefore, knows the energy requirements of every system in the plant. The plant processes on a batch system, and LaFond can follow the product through the plant, tracking the energy and labor costs on a per kilo basis as product moves from one process to another. Each week, he generates reports showing the manufacturing costs for the previous week.

“We can then look at the data in several ways,” says LaFond. “We can compare the product to every other batch of that product, or by time of year (looking for cyclical effects) or sorted by cost per kilo.” At any time, LaFond is able to take a snapshot of all the process parameters, including energy usage, and he knows if the process is on target. Knowing the factory’s energy efficiency week to week and production costs is a huge advantage, he says. “You know where you are making money and where you might be losing money. It also keeps the energy consumption and cost in your face, encouraging you to come up with new ideas on ways to operate more efficiently.”

Wenger Series VII dryer at a blueberry facility in Oregon is about 55 ft. long and locates all the fans and heaters on the outside of the dryer. Source: Wenger.

Architectural methods save energy

Controls and architectural elements of dryers, ovens and fryers can be combined to save energy. Doug Kozenski, sales manager, process prepared foods systems with Heat and Control, says his clients tend to be protein producers. And while product yields are always at the forefront, for them, making sure the product is fully cooked and safe is the critical issue. And that’s the rub. A given product will require a specific number of BTUs to be fully cooked, so the key to gaining energy efficiency is to make sure the BTUs put into an oven or fryer are distributed evenly and used fully. “If you have an oven or a fryer that applies the heat uniformly to the product,” says Kozenski, “you can cook faster and use less energy because you don’t have to slow your cook time to ensure all product is fully cooked. If an oven or fryer cannot uniformly distribute the heat, then you run the risk of having different areas of the oven or fryer cooking at different rates. To compensate, you are forced to slow your process time to ensure complete cook, and this results in added energy usage.” If the oven is balanced and uniform with heat coverage, the process is faster, product is more consistent, and in the long term, the process uses less energy.According to Bill Faivre, thermal processing specialist with Marlen, additional methods to save energy in ovens include a more efficient fan drive and an air handling system that reduces resistance, thereby reducing horsepower requirements. Though not as critical to overall energy usage in ovens, motor efficiency concerns some manufacturers to the extent that they are actually specifying premium efficiency motors over high-efficiency types, and they’re also taking another look at high-efficiency burners.

Every burner wants to have a little excess air, says Giles. Maintaining that excess air ratio can maximize the efficiency of the burner. Burner ratio control systems can maintain the ratio and provide a 2-4% increase in efficiency. Another way to improve the efficiency of the burner is to preheat the combustion air. This heat can be reclaimed from locations where heat is lost in the system, for example, in the stack. Preheating the combustion air up to 250-300°F and sometimes as high as 500°F can provide another burner efficiency improvement from 4-6%.

The Multi-Flow Fryer, installed on a potato chip processing line in Europe, features low oil volume with complete oil filtering twice per minute. Source: PPM Technologies.

Retrofits can help

Depending on the age of the dryer or oven, a retrofit may represent a less expensive option than replacing the whole system. Any system that is 15 or 20 years old, according to Sunderland, has probably been eclipsed by new technology-whether controls or baffles, so there is always room for improvement.Faivre says Marlin recently retrofitted some older, but sound, smokehouse cabinets of another manufacturer with new “roof sections.” The new roof sections were delivered with all new interior supply ducts, and a return-air plenum was factory-installed. With a new, efficient air handling system installed, this processor enjoys the benefits of an “all-new” oven for about half the price of a new oven.

While makeovers are a good way to save some money and put off buying new equipment, the thought of a retrofit as an option just doesn’t occur to them, says Schieber. He continuously gets calls from processors who would scrap their old dryer and buy new, rather than retrofit a perfectly good, existing dryer for a quarter of the cost.

From an energy point of view, a complete change of technology may make sense rather than retrofitting existing equipment. Wenger describes a processor that had been using freeze dryers in a fruit application. Because freeze drying uses compressors, electrical costs were really biting into the processor’s profit margin, and so the processor considered installing a convection dryer instead. Since the quality of the product using a convection dryer was acceptable to the processor’s customers, the processor went ahead with the project, which offered a two-year ROI. This was a major purchase for the processor, but it found another benefit. The freeze dryer, by nature, operates in batches and requires people to load and unload it. Since the convection dryer operates continuously, the operators were freed up to do other tasks.

Audit before retrofitting

Energy audits are a good way to see how practical it is to upgrade existing thermal equipment. Faivre recommends energy audits because their costs can be easily justified. His company’s audit procedure helps manufacturers optimize the processing capabilities of their existing equipment.An energy audit might reveal a processor doesn’t need to retrofit but just a change in the way it operates equipment. Dan Poirier, director of process engineering at Aeroglide, has seen it all too often. Field engineers sent to a site will make a few simple adjustments-e.g., changing bed depths and adjusting the dampers on the dryer-and an energy savings of as much as 30% can be realized. “Most people who are operating dryers don’t fully understand what’s going on inside the dryer, and there are some adjustments that have a dramatic impact on energy consumption,” says Poirier. In some cases, he says, it’s not unusual to find convection dryers using 50% more energy than they should, had they been set up properly. For example, a typical French fry dryer that should use 2,000 kW at peak efficiency might consume 3,000 kW when not properly operated. With today’s fuel costs, this can represent over $250,000 worth of wasted energy per year.

Sometimes heat loss is not so obvious, and then there are times when it shows up like a red traffic light. Ramesh Gunawardena, technology and process development manager with JBT FoodTech, explains there are several places for energy to escape in an oven: product inlet and outlet chambers, stacks, inter-connecting chambers and enclosure. This energy loss takes place in the form of hot air/vapor mixture or steam. “Sometimes you’ll go to a site and see steam leaking off the stacks of a series of boxes that are in line,” says Gunawardena. “The greater the size of the steam plume on the discharge end of the oven, the stronger the possibility that steam is being misused.” This is an indication the right amount of steam is not being delivered at the right time to the boxes.

Gunawardena suggests raising the amount of steam, effectively containing it in the first box and using progressively lower amounts later on in the process when there will be lower to no benefits from steam. This leads to more efficient steam utilization to deliver energy savings together with the desired product attributes. According to Gunawardena, “If you have good containment in the oven, the air going up the stack at the end has a greater proportion of room air and therefore lowers the temperature of the air/vapor that is being discharged to the atmosphere. This leads to opportunities to lower the volume of exhaust that needs to be treated or cleaned, producing even greater savings.”

Reclaiming the heat

While Giles talks about reclaiming heat to preheat the combustion air, another way to use reclaimed heat is to preheat the makeup air. Poirier suggests looking at the application first to see whether heat recovery systems will pay for themselves. A large dryer running infused fruit such as cranberries makes sense because this dryer already represents perhaps the biggest investment for the processor. In cereal applications, where a small dryer is used on each line, a heat recovery system for an individual line may represent an investment nearly as large as the single fruit application, which makes the cereal line dryer heat recovery system not as practical.Poirier contends, however, that a heat recovery system in the fruit dryer system applied to the makeup air can produce an energy savings greater than preheating the combustion air. In this case, a processor might realize a 10% or more savings in energy. According to Sunderland, using a heat exchanger on the exhaust system to preheat the incoming makeup air is pretty much standard practice today.

On fryers, using a booster heater hooked to the output of a heat exchanger, which captures heat at the exhaust system that would have otherwise been lost to the atmosphere, can make a big difference in reducing the energy needed to heat cooking oil, says Giles. Often heat exchangers are about 72-75% gross efficient, so replacing the heat exchanger with a more efficient (80% gross) unit can save hundreds of thousands of dollars in fuel per year when applying units capable of handling millions of BTUs per hour.

Kozenski also suggests reclaiming the combustion heat from the stacks of ovens and using this heat for a secondary process such as a fryer. This heat, typically around 800-900°F, can be used to heat the cooking oil in the fryer.

Mistretta’s first project 15 years ago was to retrofit a series of snack food fryers originally built by another manufacturer. The goal at the time was to improve the efficiency of the fryers to reduce gas consumption and increase the production rate as well. Controls, burner systems and tube assemblies were replaced, and modifications were made to the cooker plans. Heat exchangers were not recommended or provided because of higher expenses and space constraints. The net efficiency improved from 65% to 82%, and production output increased more than 35%. Final results were confirmed by Northwest Natural Gas and Oregon State University. The ROI on the project was four months. Of course, not all projects yield such dramatic ROIs. Today, net efficiencies for indirectly heated fryers are up to 84%, and up to or more than 86% for directly heated fryers.

If you use an oven, dryer, fryer or heat exchanger, you probably don’t care much about the thermodynamics of these devices. But you do care about consistent product quality and how much you spend on energy. If you’re working with equipment that is over 10 years old, you may be able to improve your product and decrease your energy usage with some basic adjustments. But in your search for assistance, remember, your mileage may vary from the theoretical numbers.

For more information:

Dan Poirier, Aeroglide, 919-851-2000, dpoirier@aeroglide.com

Don Giles, Heat and Control, 510-259-0500, dgiles@heatandcontrol.com

Doug Kozenski, Heat and Control, 847-395-6478, dougk@heatandcontrol.com

Doug Schieber, Carrier Vibrating, 502-969-3171, dschieber@carriervibrating.com

Bill Faivre, Marlen, 800-862-7536 (ext. 245), bill.faivre@marlen.com

Joseph Mistretta, FOODesign, 503-685-5030 (ext. 306), joe.mistretta@foodesign.com

Bob Sunderland, Wenger Manufacturing, 785-284-2133 (435), roberts@wenger.com

Ramesh Gunawardena, JBT FoodTech, 419-627-4315, ramesh.gunawardena@jbtc.com

Matt Ruth, 610-458-8700 ext. 274, matt.ruth@avanceon.com

An independently developed SHS fryer for restaurants and caterers, the HiFri will be available later this year in Europe. Source: HiFri B.V.

Yes, I'd like fries with that

A little more than a year ago, I had the opportunity to taste test French fries cooked at TNO Quality of Life’s laboratories in the Netherlands. Fried in super-heated steam (SHS) at temperatures in the 500°F range, these fries cooked in about the same time as conventional fries, tasted the same and looked the same. The only difference: Since they were cooked in steam, there was much less oil used (except for par frying), thus the caloric content due to fat was low. Besides being good for the heart, using less oil means additional savings for processors. While it’s easy to think of steam as “wet,” SHS steam is a dry gas-dry enough to light a match or burn paper.

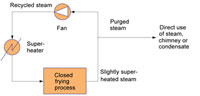

TNO’s SHS drying/frying process scheme recycles steam to cook product at temperatures to 500

TNO Spokesman Robert van den Berg says work is currently being done on large SHS equipment with partnering companies, and it’s possible an industrial version may be available in 2009. At this point, it’s unknown whether the industrial version under development will be batch-oriented like its restaurant siblings or a continuous process system. -

-Wayne Labs