Raise Cold-chain Temps From 0°F To 5°F, Save Energy and Slash Carbon Emissions

International research finds potential energy savings of 25 terawatt-hours per year and decreased carbon emissions equivalent to 3.8 million cars taken off the road.

Moving internal freezer temperatures from -18°C to -15°C can save a tremendous amount of energy should worldwide cold-chain operators adopt the move. Most freezer controls today will probably have better accuracy than a handheld IR thermometer where emissivity needs to be set for the surface being measured. Photo courtesy of Wayne Labs

A recent report entitled “Three Degrees of Change” poses an interesting question to worldwide cold-chain users. Why not increase cold-chain operating temperatures (from initial product freezing to grocery freezer) by three degrees Celsius (i.e., from -18°C to -15°C or -0.4°F to 5°F), and reap the benefits, not only in sustainability, but in energy savings as well—and maybe the best part, no investment in equipment or software is needed?

The report, authored by the International Institute of Refrigeration and the Centre for Sustainable Cooling makes a case for upping cold-chain temps, which would be imperceptible as far as food safety and quality are concerned.

This move makes sense as the preference for frozen food is increasing in developing countries. For example, 27% of households globally are expected to own a freezer in 2027, up from 24% in 2022. Much of this ownership is anticipated to be driven by middle-income countries—e.g., Turkey, India and Indonesia.

This cold-chain research has been supported by the University of Birmingham, London South Bank University and global logistics firm and principal partner in COP-28, DP World, which has set up an industry-wide consortium to explore the feasibility of this change named, “Join the Move to -15° Coalition.” COP 28 refers to the 28th meeting of the Conference of the Parties (COP) to the United Nations Climate Change Conference held at the end of 2023.

The Coalition has already been joined by leading industry organizations including: U.S. based AJC Group, A.P. Moller – Maersk (Maersk) of Denmark; Daikin of Japan; DP World; the Global Cold Chain Alliance; Switzerland’s Kuehne + Nagel International; U.S. based Lineage; Mediterranean Shipping Company (MSC) of Geneva; and Singapore-based Ocean Network Express (ONE).

If everyone worldwide in the cold chain took action, significant changes could be seen. For example:

- 17.7 million metric tonnes of carbon dioxide could be saved, the equivalent of taking 3.8 million fossil fuel-powered cars off the road annually

- Energy savings would be approximately 25 terawatt hours (TW/h), equivalent to 8.63% of the UK’s annual energy consumption

- Costs in the supply chain could be reduced by at least 5%, and in some areas by up to 12%

According to the report, Nomad Foods (Birds Eye, Findus and Iglo) announced the results of a six-month pilot study to investigate the potential to store frozen food at higher temperatures. Nomad found that storing frozen foods at -15°C instead of the industry standard -18° could reduce freezer energy consumption by more than 10% without any noticeable impact on product safety, texture, taste or nutrition.

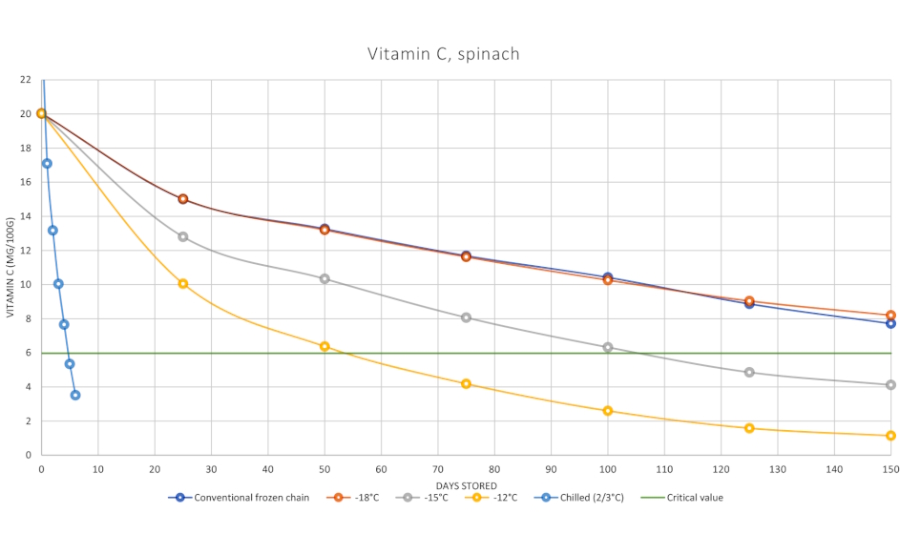

Nine frozen products were tested in the pilot, which included poultry, coated fish, natural fish, vegetables, plant-based foods and pizza. Four temperatures (ranging from -18 to -9°C) and eight key areas of concern (including, for example, food safety, texture, nutrition, energy use and packaging impact) were analyzed. The results showed no significant change to products across the areas tested at the higher temperatures except for mixed vegetables at -9°C and salmon fillets at -12°C. There were also some issues with vitamin C for vegetables when stored at the highest test temperature of -9°C. (See the graph.)

FE spoke with Thomas Eskesen, recently appointed chairman of the Join the Move to -15° Coalition to get a few details.

Evolution of Vitamin C content for frozen spinach stored at different temperatures (modeled using the Frisbee and ENOUGH Tool (Leducq et al, 2023)).* Evolution of Vitamin C content for frozen spinach stored at different temperatures (modeled using the Frisbee and ENOUGH Tool (Leducq et al, 2023)).* |

FE: Since your announcement of the three-degree Celsius change (5.4 degree change in F) in November, what kind of feedback have you had from food companies, government regulators, freezer and refrigeration equipment suppliers, logistics and supply chain people?

Thomas Eskesen: So far, the response has been extremely positive, with many key industry leaders understanding the critical need for change and the positive impact that a three-degree [Celsius] temperature shift could have on the environment, particularly given that this is a change that requires no new technology.

We are still in the early days of establishing the coalition. Before steps can be taken to engage with regulators, we need to pool our collective knowledge so that our conversations can be as practical and realistic as possible, without diminishing the ambition.

FE: Have any other food companies besides Nomad done any specific testing of food products at the “new temperature of -15°C”?

Eskesen: We are pleased to see that other research is being done on this topic. Both Nomad Foods and the Cold Chain Federation recently released reports that confirmed that a change in temperature set-points could reduce freezer energy consumption without impacting food safety. In late 2023, Unilever announced that it would grant a free non-exclusive license to the ice-cream industry for patents that could help the industry reformulate their ice-cream products so that they could remain stable at a temperature of -12°C.

As a coalition, we will continue to work closely with our members and with academia to ensure that we achieve the rigorous underpinning that is essential for us to make change.

Thomas Eskesen, chairman of the Join the Move to -15° Coalition.

Thomas Eskesen, chairman of the Join the Move to -15° Coalition.FE: Interestingly enough, our FDA (in 21 CFR Title 21) doesn’t list an appropriate frozen temperature for production and process controls, but it does for refrigerated foods and hot foods. It simply says under (3)(ii) “Maintaining frozen foods in a frozen state.” How did we in the U.S. arrive at 0°F (-18°C) as an ideal frozen temperature?

Eskesen: When the industry set-point was established over 90 years ago, it was because -18°C was believed to provide a good margin for safety. Technology has come a long way since then, and the “Three Degrees of Change” report has demonstrated that it is possible to move to -15°C without compromising food safety. We have not been able to find evidence of a scientifically proven reason for adopting the current norms, outside of the sensible reason that it was safe. But, given the advances in technology over the decades and the pressure to decarbonize supply chains, we believe those norms are overdue a revision.

FE: Do other worldwide governing bodies set a specific frozen food temperature for storage, for transit?

Eskesen: Currently, there is a complex mix of regulations and guidelines surrounding temperature set points, some of which have not been reviewed and assessed for a number of years. Our intention is to map out the current state of global temperature set points and then plan to engage in due course to discuss the possibilities of a global shift.

FE: By adopting the change, which part of the cold chain stands to benefit the most? Food company storage, frozen warehouse, freight (air, sea, land)?

Eskesen: The “Three Degrees of Change” report considered the whole frozen food cold chain within its study, from the point of freezing to transport and storage, to consumers picking it up from supermarket shelves. The anticipated economic impact of the move includes energy savings ranging from 5% to 7%, and in some areas, 12%, with variations depending on the specific segment within the cold chain. It’s important to note that the cost of energy will be company specific, but the savings are significant.

What’s critical is that the benefits of a -15°C cold chain can only be fully realized if all the actors along the chain move to the new temperature regime.

FE: While sustainability and decreasing emissions is both noble and altruistic, I would think that the potential cost savings in fuel and energy would be a tremendous magnet to draw people in. What seems more important to cold chain participants?

Eskesen: The “Three Degrees of Change” research shows that there is a substantial prize to be won if we can work towards this change. Industry is under more pressure than ever before to decarbonize, especially as we move towards net-zero 2050. Our coalition intends to bring industry together to work towards a collective solution that can help us achieve our shared net-zero ambition. This is a rare example of an initiative that should both save costs and reduce emissions with no new technology or investment required.

FE: I saw that you expect to have more information available in the early spring. How is that goal doing? What kind of information will you have? Any other comments?

Eskesen: The academics behind the “Three Degrees of Change” report intend to release a full report of their findings this year. Given the research being done in this space, we’re confident that there will be more research reports released in due course.

FE: How can participants in the cold chain get involved with your program? What is the future of your program?

Eskesen: The coalition’s main objective is to rally everyone together for collective action, as this is a move that cannot be undertaken by any single entity alone. Moving forward, the coalition will aim to spearhead viable decarbonization efforts for the sector across the globe while driving food resource resilience and energy saving for a critical part of the supply chain. It will focus on galvanizing debate, exploring end-to-end solutions and creating a magnetic case for change.

Any interested parties can join the coalition. All they need to do is contribute time, expertise and a willingness to share knowledge. If you’re interested in becoming a member, visit https://www.dpworld.com/sustainability/jointhemovetominus15 to register or download the report, “Three Degrees of Change.”

Reference:

*Leducq, D., Evans, J., Foster, A., Verboven, P. and Alvarez, G. “A tool to evaluate and optimize GHG emissions in food supply.” IIR International Congress of Refrigeration (IRC), 2023.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!