FA&M Post Show

There Was Plenty to See at FA&M 2024

Even though there were only six months in between iterations, FA&M still delivered on the networking and educational content.

Grant McKinley provided the FA&M audience with an update regarding Kerry's Rome, GA, facility, FE's 2022 Sustainable Plant of the Year. Image courtesy of Tracy DiCello

As events go, FOOD ENGINEERING’s Food Automation & Manufacturing Symposium and Expo (FA&M) has always been on the smaller side. In my opinion, and of course I’m biased, that’s a benefit to both attendees and exhibitors. FA&M presents an opportunity for real connections to be made, and the 2024 event was no different.

Networking

The best time to see connections being made was at the frequent networking receptions or breaks. For an event that’s essentially a day-and-a-half long given the spaced out format of activities, the amount of time spent mingling over food and drinks might seem outsized compared to session programming. But that frequency is what gave this year’s FA&M a relaxed atmosphere which made it easy to approach people from a wide variety of roles within the food and beverage space, from manufacturers to equipment suppliers to design-build firms to providers of staffing services.

Interestingly, this was the first year in a couple of years that didn’t have a golf outing or a whiskey tasting. The lack of those two events was made up for by Mother Nature offering a solar eclipse, although Bonita Springs, FL, was far from the path of totality. We also had the final game of the Men’s NCAA basketball tournament being played. Even though the show had nothing to do with either of those events, the fact that they were happening created an energetic vibe and an instant conversation starter.

The expo hall wasn’t filled with machines or demonstrations. That’s not to say that there weren’t machines or demonstrations, but the focus was on interacting with each other instead of having to shout above the din of various pieces of running equipment. Personally, that sort of environment gives me the chance to learn more about a company, product or service as opposed to a quick summary before having to dart off to the next appointment. It proved that, once again, I’m more likely to contact someone I’ve met at FA&M as an expert source for a story, video or podcast because I’ve had the chance to sit down and truly get to know the person I’m speaking with and be able to pick their brain in their area of expertise.

Education

Of course, the stars of the show are the education sessions and the people presenting them. As one of the people tasked with selecting topics and speakers, I was particularly proud of the lineup we assembled this year, and it didn’t disappoint.

Automation Alley’s Tom Kelly got the entire show kicked off with an in-depth look at not just automation, but manufacturing in general. As he put it during his session, you might not like what he had to say, but what he said definitely made you think. While it’s difficult to completely summarize all that he covered in his keynote, manufacturers that break the traditional model of manufacturing to benefit consumers are the ones that have a better chance of reaching the top of their category. This may be achieved through distributed manufacturing where production is basically shifted to the point of sale to bring in the power of mass customization.

Kelly’s session nicely set up Wayne McIntyre, CEO of ReLocalize, who spoke more in-depth about his company’s autonomous micro-factories, which puts that concept of decentralized manufacturing into practice. Practical applications for this rely primarily on a close proximity to the right materials, meaning the fewer ingredients the better, but technology is rapidly making this type of manufacturing a reality.

Billy Gillespie, who provided FA&M’s Day 1 keynote last year, and Andy Daly, also from Microsoft, kicked off the second day of sessions this year. Their keynote picked up from last year’s with how AI and programs like Microsoft’s Copilot are impacting manufacturing by boosting productivity and helping to navigate things like the supply chain. It was interesting to see how so much had changed in just the six months since the last presentation.

Case Studies

My favorite part of FA&M every year are the projects that we get to see and learn more about. Leading the way was John “Jocko” Krbechek, vice president of engineering for Taylor Farms’ foodservice division, and Dennis Group senior partner Jeff Lewandoski sharing the incredible tale of how Taylor Farms was able to restart full production just a year after its Salinas, Calif., production facility, the company’s biggest, burned to the ground. It was a fascinating story, so much so that it earned FOOD ENGINEERING’s first-ever “runner up” recognition for Plant of the Year.

Grant McKinlay, Kerry Group’s senior director of continuous improvement, was there on Day 2 to share how our 2022 Sustainable Plant of the Year award winner was doing in the years since taking home the award. No surprise given how meticulously the project was planned and executed, it’s met its initial goals and is now proceeding to best them and set the bar for future Kerry projects.

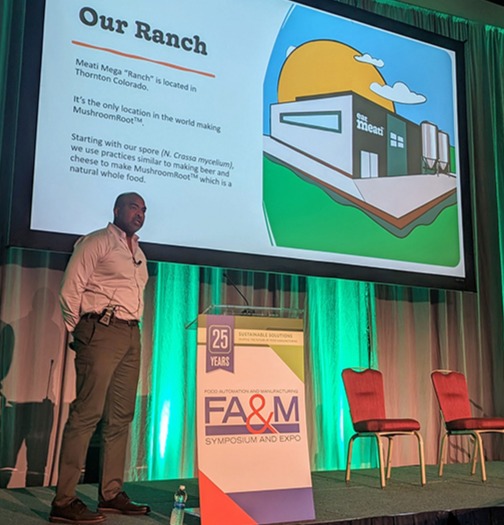

We also had Joe Johnston, SVP of engineering and operations at Meati Foods, round out Day 1 by talking about the Mega Ranch, this year’s Sustainable Plant of the Year winner. Joe Machetta, head of operations at JBS USA, closed the show presenting our Plant of the Year winner, JBS’ Principe facility. I’m not going to write more about those right now. You either had to be there or you can read about the JBS project in last month’s issue. We’ll be profiling Meati Foods’ Mega Ranch in our July issue.

It’s pretty amazing how something that’s taken so much planning and preparation from so many people these past sixth months can come and go as quickly as it has, especially considering it ran for three days. It was great to once again see so many people and catch up with them, even it had only been sixth months since I last saw many of them. All of us at FOOD ENGINEERING are so appreciative of our speakers, attendees and sponsors who made the show possible—thank you!

Now it’s time to roll up our sleeves and get to work planning the 2025 event. Hope to see you there.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!