Why the IP69K Rating is Essential For Bearings in the Food And Beverage Industry

Image courtesy of Vital Farms

The ingress protection, or IP, rating system was developed by ISO and the IEC. The standard measures an enclosure’s ability to withstand contamination ingress. While it was originally created for electrical components, it soon became applicable to the mechanical world.

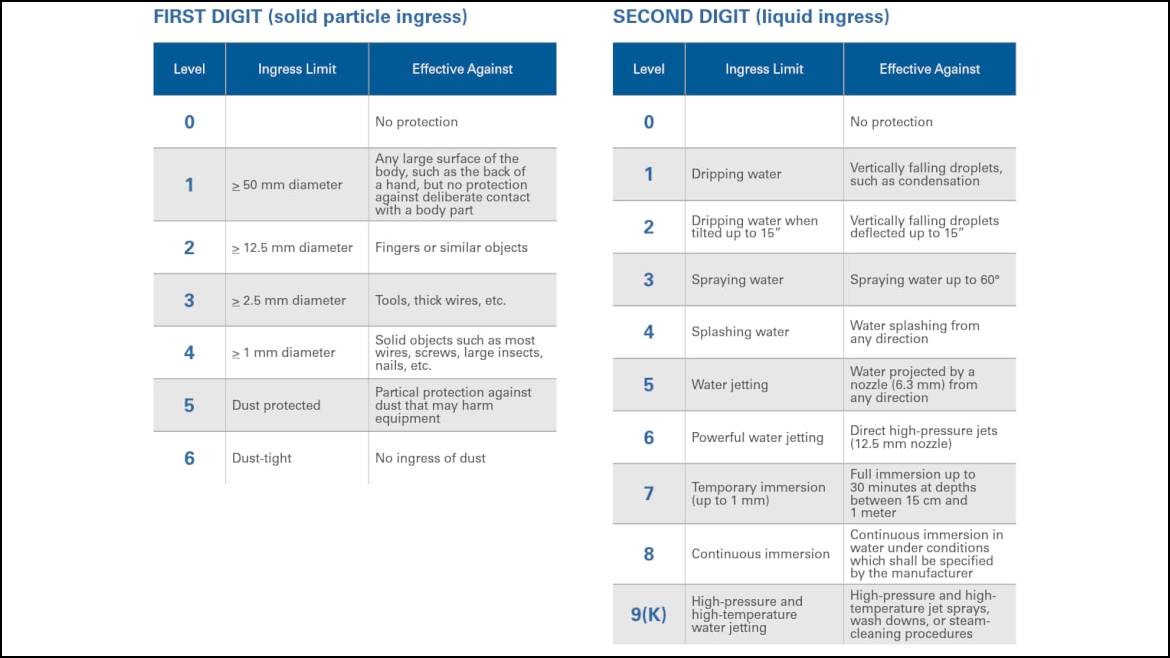

The IP rating scale has a two-character format. The first character represents the degree of protection against solid-particle contaminants. The second represents the level of protection against liquids. As you can see in the IP rating scale below, IP69K offers the highest level of protection against both solids and liquids.

Ingress Protection (IP) Ratings. Adapted from “A Brief Overview of Ingress Protection (IP) Ratings,” by Leviton Manufacturing Co., Inc. https://www.leviton.com/en/products/industry-solutions/food-beverage-processing/what-is-ip69k

IP69K in the Food and Beverage Industry

There’s a high demand to resist contaminants in food and beverage plants. Every day, these facilities contend with food particles from processing, heavy and regular washdown processes, and food safety regulations. These factors are all driving the industry to make the shift toward IP69K-rated products.

These products are typically more hygienic and designed to withstand bacterial contaminants. They also perform better in very wet environments and washdown conditions, which ultimately helps increase uptime and lower maintenance costs. Ideal applications for IP69K-rated products include anything that involves food contact (or the potential for food contact), as well as areas that are subject to washdown or have regular contact with liquids.

The severity of washdown conditions could be a factor in determining if you need an IP69K-rated bearing. The 9K indicates a resistance to high-temperature, high-pressure water spray. IP66, 67 or 68 products may perform well in less demanding applications. But when the presence of bacteria is possible and washdown is frequent, IP69K products are going to perform the best and be the most hygienic. This is especially critical for anything water can damage, such as control panels, electric motors and bearings.

IP69K and Bearings

Bearings are used in almost every step of food and beverage processing—appearing in conveyors, washers, mixers, fryers, ovens and other equipment. These bearings undergo exceedingly difficult operating conditions, including heavy washdowns, in critical, food-safe areas. No matter the industry, keeping contaminants out of bearings is crucial to performance.

IP69K-rated bearings offer multiple benefits. Keeping solid contaminants out of the bearing helps avoid damage to rings and rolling elements. Keeping liquids out helps ensure lubricant is not diluted and washed out. This allows the bearing to operate as intended while maximizing life and minimizing downtime. The improved seals usually associated with IP69K-rated bearings better retain lubricant. This reduces the likelihood that lubricant will come into contact with food—increasing food safety.

Bearings earn the IP69K rating in one of two ways:

- Primary bearing seals. These seals are usually made of a rubber compound that is chemically resistant to stand up to washdowns. This rubber compound is often used as multiple contacting seal lips that create added barriers to keep contaminants out. There is typically some form of deflecting device used in conjunction with the lip seals that will rotate with the shaft and use the centrifugal forces of the shaft rotation to fling away solid or liquid contaminants. This is commonly known as a flinger.

- End covers with simple primary seals. These end covers bolt onto the sides of the bearing housings and provide an additional barrier to contaminants.

Both styles can be used with multiple lubrication options such as food-grade greases and solid lubricants—providing additional layers of contamination protection.

Each of these designs has its pros and cons. The primary seal standalone option maintains the footprint of any similar sized bearing and does not provide any place for bacteria to sit and grow. However, the multiple contacting seal lips can increase the torque needed to turn a shaft compared to conventional seal designs. The end cover option may not increase torque, but the end covers themselves have been known to harbor bacterial growths and are difficult to clean. You will also find that many housings for IP69K-rated bearings do not contain provisions for relubrication. This is to remove another potential area for contamination. Whether filled with grease or solid lubricant, these bearings are generally considered lubricated for life.

Summary

IP ratings designate the level to which a product is protected from solid and liquid contamination. The first character corresponds to the solids, the second character to liquids. The incredibly demanding operating application and washdown conditions, along with food safety concerns and regulations, have driven a shift toward IP69K-rated products in the food and beverage industry. These products can perform better and in a more hygienic manner than their conventional counterparts. From a bearing perspective, this rating is achieved by more robust seals and flingers and potentially auxiliary end covers. The use of such, along with proper food-grade grease or solid lubricant, can be a great option to reduce maintenance needs, improve food safety and reduce downtime. All of which can lead to an increased volume of safer food and beverage products flowing out the door and onto store shelves.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!