Odor Control

Natural Neutralizers are the Key Ingredient for Safe and Effective Odor Control

By leveraging plant-based and scientifically proven formulations, food processors can keep odors at bay and operations on track.

Photo courtesy of Getty Images / wildpixel

Mitigating odorous off gas is a persistent challenge for industrial food processors. From pungent fish sauces to lingering cheese aromas, these unpleasant odors negatively impact both employee comfort and neighborly relations.

Traditional odor abatement methods typically mask unwanted smells with fragrances, but these efforts result in temporary solutions at best or air toxicity issues at worst. Instead, long-lasting and targeted solutions are required.

Conversely, molecular odor neutralization with plant-based formulations provides a safe, effective and cost-efficient approach to tackling unpleasant odors at their sources. This article delves into the science behind these neutralizers, exploring the ways they are transforming odor control strategies in food processing facilities. With the help of experienced suppliers with scientific and operational expertise, food processors can effectively mitigate unwanted smells in their facilities, thereby creating a more pleasant environment for all working within the plant or living in its vicinity.

The Science of Molecular Odor Abatement

Industrial odor control utilizes a well-established scientific approach centered on molecular polarity and binding interactions. This targeted strategy exploits the polar structure of many odorous molecules in industrial environments, such as hydrogen sulfide and mercaptans.

Polar molecules exhibit an uneven distribution of electrical charges across their constituent atoms, resulting in a slight positive charge on one end and a slight negative charge on the other. Plant-based natural neutralizers are meticulously formulated to maximize interactions with malodorous molecules based on polarity.

This strategically manufactured binding approach is called adsorption, where neutralizing formulations bind to the surface of pungent particles. Next, neutralizers fully envelop the offending molecules through absorption when they combine, deactivating the smell. These processes immobilize the malodorous compounds, preventing them from interacting with olfactory receptors in the human nose, and rendering them unable to elicit an unpleasant odor response.

These reactions neutralize the majority of volatile organic compounds (VOCs)—the components that cause scents—in the air, leaving behind molecules that are undetectable to the senses. By leveraging the principles of polarity and binding, industrial odor neutralizers significantly reduce unpleasant odors in industrial settings.

The effectiveness of an odor neutralizer hinges on its ability to establish strong binding interactions with the specific odor molecules present in the environment, so it is critical to strategically select neutralizers specific to various industrial applications for best results.

Proven Natural Odor Solutions for Diverse Industrial Needs

Top suppliers of natural odor control products leverage their extensive knowledge, years of research and cutting-edge laboratory technologies to develop specialized odor-fighting formulations. Each blend is designed for maximum effectiveness in a few targeted settings, typically crafted for a specific industrial sector, such as food and beverage processing. Even within each discipline, there may be various solutions. For example, tuna waste exhibits a very different odor profile than wastewater laden with formaldehydes from preservatives.

While certain situations require custom formulations, most applications benefit from standard blends designed to target most airborne contaminants generated by their typical processes. These standard blends effectively neutralize odorous emissions that can cause problems for employees and nearby communities. Advantages of these solutions include:

- Industry expertise: End users benefit from the supplier's deep understanding of industrial processes gained through experience and testing across numerous facilities in various geographic areas.

- Faster implementation: Readily available off-the-shelf solutions reduce lead time.

- Streamlined startup: Turnkey systems minimize setup and commissioning time.

- Proven performance: Successful application across various industries provides confidence in the products’ effectiveness.

- Adaptable to process changes: Flexible formulations provide end users with the freedom to switch raw materials and optimize their operations without fear of requiring new custom odor control blends.

- Reliable support: Suppliers can provide optimal support because they are deeply familiar with the products, as they are used by many of their customers.

While standard formulations address the needs of most plants, some facilities may require custom odor control blends. In these cases, experienced suppliers can prescribe or create specialized solutions.

Long-lasting Sample Collection for Odor Analysis

The procedure begins with collecting air samples directly from the facility during various production stages (Figure 1), using specialized containers to preserve sample life.

In the past, Tedlar bags were commonly employed to collect samples. However, Markes thermal desorption tubes provide an innovative and modern technique both for sampling odors at high concentration and preserving them for weeks, compared to mere hours. This extended window allows for greater flexibility in scheduling laboratory analysis, streamlining the overall process.

Each tube contains sorbent material designed to efficiently capture airborne odor molecules during sampling (Figure 2). Air is drawn through the tube by a pump for up to about five minutes, highly concentrating any VOCs present in the sample, even when odorous molecules are present in trace amounts.

This concentration helps ensure accurate identification of every compound, from the most obvious to the most elusive. Upon collection, the Markes tubes are sealed and transported to a laboratory for analysis (Figure 3).

In the lab, the tubes are then heated, gently releasing the odor molecules from the sorbent material via thermal desorption for further investigation. This concentrated sample is introduced to a powerful analytical instrument, such as a gas chromatograph-mass spectrometer (GC-MS), for definitive molecular identification (Figure 4).

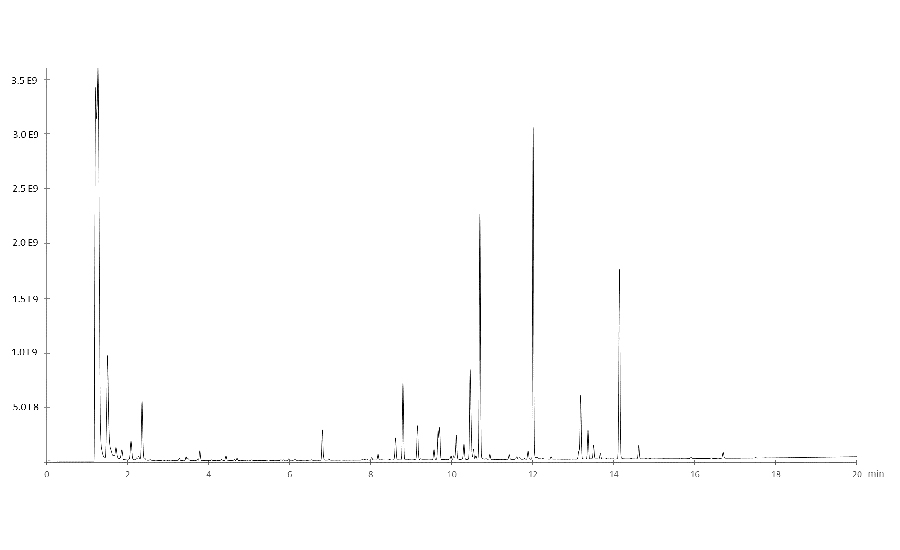

A GC-MS produces a chromatogram, which plots detector response (y-axis) against retention time (x-axis), with each peak in the chromatogram representing a unique chemical compound (Figure 5). Each component’s identity can be deduced by analyzing the fragmentation pattern, empowering scientists to understand the chemical make-up of each malodor.

Equipped with this information, scientists formulate particular plant oil blends to neutralize the substances of concern, so every product prescription is tailored to specific plant needs for optimal odor control.

Due to enhanced sample life and low-volume compatibility, Markes thermal desorption tubes play a vital role in ensuring efficient and accurate odor analysis in various industrial settings. This technology—combined with advanced gas analytical technologies, like GC-MS, and supplier expertise—empowers suppliers, and their customers, to tackle challenging odor control issues with confidence.&

Adsorption and Absorption in a Liquid Fertilizer Production Plant

A U.S.-based food processor that converts food scraps into liquid fertilizer was facing mounting odor complaints. Located in an industrial and commercial area close to other facilities (Figure 6), the processor needed a solution to mitigate the problem before it got out of hand.

Odors often originate from handling, manufacturing and wastewater treatment in food processing operations. This processor invited Ecosorb, a supplier of plant-based industrial odor neutralizers, to sample air around the facility, and to then prescribe a standard formulation to mitigate the malodors drifting to its neighbors. The team discovered high concentrations of hydrogen sulfide, mercaptans and amines emanating from the exhaust stacks during final production stages, so it began dosing Ecosorb 806—which specializes in neutralizing these compounds via both adsorption and absorption—at each exhaust nozzle using a compressor to atomize the dosing.

Upon deployment, complaints from the community disappeared almost immediately, enabling the processor to maintain neighborly relations, and to continue producing liquid fertilizer without fear of interruption.

Drive Continuous Production with Safeguards Against Malodors

By applying the right plant-based odor neutralizers in their food plants and facilities, processors can effectively mitigate foul odors using safe, environmentally friendly and cost-efficient methods. These formulations do not mask smells, but instead mitigate them by enveloping or neutralizing the odor-causing molecules found in facility air.

These mitigation techniques empower food processors to redirect their time from odor control and complaint handling, and instead focus on maximizing production and remaining competitive in continuously evolving markets.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!