Top Plant-Based Products

Top 2024 Advances in Alternative Protein

November 14, 2024

Top Plant-Based Products

Top 2024 Advances in Alternative Protein

November 14, 2024Image courtesy of Beyond Meat

Encompassing plant-based products, cellular agriculture and precision fermentation, the alternative protein category is diverse—and growing.

Research firm Markets and Markets projected the global alternative protein market would reach $15.7 billion in 2024 and grow at a compound annual growth rate of 9.9% over the next five years, surpassing $25 billion in 2029.

However, simply offering these options is no longer enough. As demand for alternative protein products increases, manufacturers are turning to technology to enhance nutrition and flavor profiles and improve scalability and—ultimately—offer prices that are competitive with traditional protein.

Technological Advances

Several alternative protein manufacturers have unveiled process improvements or announced investments in equipment and facilities.

In September, Rebellyous Foods, maker of plant-based chicken, introduced its Mock 2 Production System at RMS Foods’ facility in New Mexico. The fully continuous, automated and chilled dough substrate processing system reduces manufacturing costs, compared to conventional methods. It can produce a range of plant-based meat products at volumes of 2,500-5,000 lb./hr. on a single processing line.

"Our Mock 2 technology is the key to meeting the unmet demand for delicious, affordable plant-based options," says Christie Lagally, founder and CEO of Rebellyous Foods. "We're not just competing on price and volume—we're setting new standards for texture, flavor and quality."

Earlier this year, Colorado-based Demolish Foods unveiled its Gen3 platform that can produce plant-based meats, as well as cultivated meat hybrids. It is designed to replicate the chewiness, juiciness and changing mouthfeel of traditional meat as it is chewed and broken down. To produce muscle fibers out of plant proteins that mimic the size, tensile strength and nutritional profile of animal muscle fibers, Demolish Foods uses its patent-pending "protein chaining" technology.

Believer Meats also entered into a partnership with equipment supplier GEA—which is in the process of opening its own alternative protein facility in Wisconsin—to co-develop technologies and processes to improve the unit economics and sustainability of cultivated meat production.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

Specifically, Believer Meats is constructing a cultivated meat production facility in Wilson, N.C. that is set to become operational in 2025. The facility will have the capacity to produce at least 12,000 metric tons of cultivated chicken annually. GEA will develop and commission proprietary bioreactors for Believer’s cell-cultivation technology.

“We are taking the next step in innovating state-of-the-art technology and process engineering capabilities needed to produce cultivated meat products at the right cost,” says Believer Meats CEO Gustavo Burger. “The partnership with GEA will help maximize production yields efficiently and sustainably, which are top priorities for Believer. The cultivated meat industry is forging a new path that has never been traveled. We are thrilled to partner with GEA and are very optimistic about the future.”

Israel-based Steakholder Foods continues to expand its capabilities in 3D printing of plant-based meat and seafood. In September, the company opened a demonstration center to showcase its 3D printers—the MX200 and HD144.

The MX200 utilizes fused paste layering (FPL) technology to replicate the textures of traditional meat by combining plant-based proteins and fats. It offers customization for various meat alternatives. The HD144 employs drop location in space (DLS) technology, allowing precise placement of plant-based ingredients to create seafood textures, from tender fish to flaky fillets.

Steakholder Foods also has partnered with sister frozen food manufacturers Premazon and Bondor Foods, providing them with fish premixes to develop into plant-based products.

“We are glad to announce this commercial sale of our proprietary premixes and to move into large-scale production,” says Steakholder Foods CEO Arik Kaufman. “This agreement is a testament to the successful collaboration between our companies throughout the development phase to create a truly innovative new product line and validates the market potential for plant-based seafood alternatives.”

Microalgae protein company Brevel, Ltd., also based in Israel, opened a 27,000-sq.-ft. production facility that will produce protein extracted from microalgae belonging to the chlorella family. The company expects the new facility to be operational in 2025.

Alternative protein sources aren’t only reserved for human consumption. In January, PawCo—maker of GreenMeat, a plant-based meat tailored for pet food—launched two dog food products developed with fermented protein: LuxBites and InstaBites. LuxBites also feature postbiotics for gut health, while InstaBites are shelf-stable and designed for convenience.

PawCo reports it uses artificial intelligence (AI) to optimize nutrition and improve the palatability of its offerings.

"Our mission at PawCo is to ensure every dog and dog owner has access to healthy and affordable meal alternatives, without sacrificing other animals' lives," says Mahsa Vazin, founder and CEO of PawCo Foods. "We are using AI in various parts of our process to ensure the food is optimized for dogs while improving the palatability and taste of our products."

Product Innovation

As producers refine manufacturing processes, they’re launching products with enhanced nutrition profiles, while others are entering the market for the first time.

Earlier this year, Beyond Meat introduced the fourth generation of its Beyond Burger, Beyond Beef and Beyond Sausage.

In these products, the company switched to avocado oil to reduce saturated fat content and boost flavor. Beyond Meat also increased the protein content to 21g in Beyond Burger and Beyond Beef and 17g in Beyond Sausage. The company also added plant-based ingredients, such as red lentil and fava bean protein, to the beef and sausage products.

“We know that health is a top driver for the plant-based meat category, and with the advancements in taste and nutrition of our new Beyond Burger and Beyond Beef, we’re giving consumers a really compelling reason to make the switch,” says Akerho (AK) Oghoghomeh, chief marketing officer, Beyond Meat.

The company also revamped and expanded its Beyond Crumbles line to include an Italian-style sausage option, made with pea protein, rice protein and fava bean protein. Designed to go from frozen to finished in minutes, Beyond Crumbles have 12g of protein per serving with less than 1g of saturated fat.

Beyond Meat typically aims to recreate the experience of meat products with plant-based options, but in July, the company introduced Beyond Sun Sausage, which was not designed to replicate pork, beef or poultry. Instead, Beyond Sun Sausage was developed as a standalone protein product, made with spinach, bell peppers, yellow peas, brown rice, red lentils and fava beans. Each link includes 12g of protein, 1g of saturated fat and no cholesterol.

“We’re thrilled to introduce a completely new innovation to the plant-based category with the addition of our wholesome, flavor-forward Beyond Sun Sausage,” says Dariush Ajami, chief innovation officer, Beyond Meat. “Filled with clean plant proteins including yellow peas, brown rice, fava beans and red lentils, this launch further exemplifies our industry-leading commitment to raising the nutrition bar for plant-based meats and creating delicious, healthy products.”

In March, Kraft Heinz announced a joint venture with TheNotCompany, Inc. and introduced the first plant-based meat products launched under the Oscar Mayer brand: NotHotDogs and NotSausages.

“We know people are hungry for plant-based meat options from brands they know and trust,” says Lucho Lopez-May, CEO, The Kraft Heinz Not Company. “In launching the joint venture’s first product in the plant-based meat category, we saw an opportunity to satisfy these consumer cravings, leveraging NotCo’s revolutionary AI technology and the power, equity and legacy of the Oscar Mayer brand.”

Before the Butcher also expanded into the plant-based sausage category with a gluten-free breakfast sausage patty. Manufactured in San Diego, Calif., the sausage patties have a 12-month frozen shelf life and a five-day refrigerated shelf life after thawing.

In July, Juicy Marbles, maker of plant-based steaks and tenderloin, introduced Baby Ribs with its "Marble 3.0" recipe. It offers 32g of protein per serving, with a complete amino acid profile; no thickeners, binders or preservatives; micronutrients such as iron, zinc, selenium and B vitamins; and 100% non-GMO ingredients.

To recreate the eating experience of ribs, Juicy Marbles developed “bones” made from plant protein. They’re 100% compostable and edible.

“A lot of people are adding plant-based meats to their protein portfolio, and we want them to rest assured that they're not eating something that's just mimicking the sensory aspects of meat, but also provides the essential micronutrients our bodies need to function,” says Vladimir Mićković, Juicy Marbles co-founder and chief brand officer. “The food equivalent of style and substance. The rest of the Juicy Marbles portfolio will also graduate to the ‘Marble 3.0’ recipe by the end of 2024.”

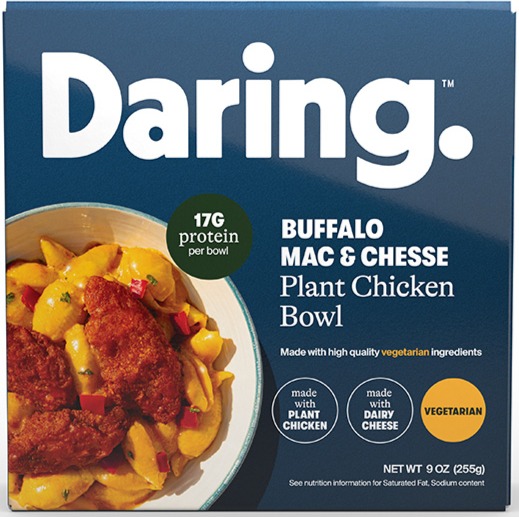

In October, Daring Foods debuted two vegetarian frozen entrees—the Buffalo Mac and Cheese Plant Chicken Bowl and the Queso Burrito Plant Chicken Bowl—that feature the brand’s soy protein-based chicken alternative alongside traditional dairy-based cheese.

Daring Foods CEO Jeff Gendelman addressed the decision to incorporate traditional cheese into the bowls.

"In doing product research, we looked at what was succeeding in food service at places like Burger King and Starbucks where flexitarian and omnivore consumers were eating products like plant beef and plant sausage patties sitting on top of egg and dairy cheese,” Gendelman says. “Including small amounts of dairy cheese made flexitarian and omnivore consumers more receptive to plant-based meat products. With Daring's new vegetarian bowls, we'll be able to speak to these consumers and introduce them to our vegan plant chicken in a format that they are more open to trying."

Meanwhile, Nestlé aimed to capitalize on the economic potential of plant-based protein, launching Maggi Rindecarne, a plant-based meat alternative designed to extend meals, in Chile. The mix of soy and spices allows consumers to prepare a dish combining meat and plant-based proteins, doubling the amount of servings at an affordable price.

"Our team of experts and chefs developed a tailored solution which brings an equivalent amount of protein in an affordable way to consumers in Latin America,” says Swen Rabe, head of Nestlé's Product and Technology Center for Food. “Our innovation ensures the familiar taste and texture of mincemeat, is shelf-stable and easy-to-use.”

In the seafood category, startup BettaF!sh introduced SAL-NOM, a plant-based alternative to hot-smoked salmon. Made from European organic seaweed, fava bean and pea proteins, SAL-NOM offers an authentic sea flavor without the use of soy and wheat. The product serves as a source of protein, omega-3 fatty acids and fiber, which are essential for a balanced diet.

“SAL-NOM is not just a product; it showcases our dedication to innovation, sustainability and taste,” says Deniz Ficicioglu, CEO of BettaF!sh. “By leveraging the natural benefits of seaweed, we offer a fish alternative that is not only delicious but also significantly contributes to the protection of our oceans and personal health.”